Connector Devices

Device Types & When to Use Them

This section outlines the primary power device types and highlights when each is best used based on environment, capacity, and application requirements.

IEC Pin & Sleeve Devices

IEC Pin & Sleeve devices are designed for reliable, lockable power connections in demanding environments. These industrial-grade devices are the most common choice for modular power whips used in data centers and critical facilities.

When to use:

- Raised floors or overhead feeds

- Washdown or moisture-prone environments

- Standard PDU whips

Why choose IEC:

- Rugged construction with lockable mating

- Keyed to prevent mis-mating

- Globally recognized/compatible

NEMA Twist-Lock Devices

NEMA Twist-Lock devices are ideal for general power distribution in conditioned indoor spaces. They provide secure plug-and-play connections for rack PDUs and related equipment.

When to use:

- Controlled, dry environments

- Standard IT racks and office power feeds

- Best for general rack power or office PDUs

Why choose NEMA:

- Secure locking engagement

- Cost-effective and widely available

- Familiar form factor for general applications

- Economical, compact, easy to plug/unplug in conditioned indoor environments

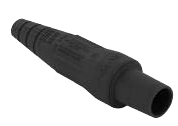

Single-Pole Cam-Type Devices

Single-pole Cam-Type devices are built for high-capacity or temporary power scenarios where quick setup and teardown are needed, such as temporary distribution or large loads.

When to use:

- Mobile or temporary event power

- UPS, generator, or maintenance feeds

- High current loads (up to 400A)

Why choose Cam-Type:

- Fast connect/disconnect

- Phase-coded colors for clarity

- High ampacity for temporary or redundant feeds

- Secure, live or off, tool-less setup

Mechanical Lug Connections

Mechanical lugs provide fixed, high-capacity terminations for permanent infrastructure where cables are hard-terminated into panels or equipment. Lugs typically require qualified electrician installation with equipment turned off during installation.

When to use:

- Handles very high current and permanent connections into switchboards, PDUs, or distribution panels

Why choose Lugs:

- High ampacity support

- Long-term reliability

- Best for main feeds and hard-wired terminations

Power Connector Types Comparison

Use the table below to compare power connector types by design, electrical ratings, safety features, and typical applications to help identify the best option for your installation.

| Connector Type | Design & Construction | Voltage / Amp Ratings | Safety & Features | Flexibility / Installation | Typical Applications |

|---|---|---|---|---|---|

| IEC Pin & Sleeve (IEC 60309) | Round, keyed multi-pin design with color-coded non-metallic housings; watertight construction (IP67/IP69K). |

20A – 100A

120V – 600V AC Single or three-phase | Ground-first sequential contact engagement, lockable covers, shrouded pins, and OSHA LOTO-compliant designs. | Moderate flexibility with plug-and-play installation; ideal for harsh or wet environments. | Permanent or semi-permanent PDU whips under raised floors or in high-density rack environments. |

| NEMA (Twist-Lock or Straight-Blade) | Flat-blade connectors standardized by NEMA with molded thermoplastic housings. |

15A – 60A

125V – 600V AC | Mechanical locking (Twist-Lock) and polarized designs to prevent mismating. | Compact, widely used, and easy to replace; limited to dry, indoor environments. | Rack PDUs and plug-in equipment fed from floor whips or overhead busways in controlled spaces. |

| Cam-Lock (Single-Pole) | Single-pole locking connectors with elastomer housings and color-coded sleeves. |

150A – 400A (per pole)

Up to 600V AC/DC | Secure twist-lock mechanism, finger-safe shrouds, and E-, P-, or reverse-sex configurations. | Highly flexible with quick connect/disconnect; ideal for temporary or high-capacity power feeds. | Temporary power, UPS tie-ins, generator hookups, and maintenance bypass systems. |

| Mechanical / Compression Lugs | Bare crimped or bolted cable terminations, typically constructed from aluminum or copper. |

100A – 4000A+

600V AC/DC and above | Requires bolted terminations and torque verification; exposed conductors unless enclosed. | Least flexible; permanent or semi-permanent connections requiring tools and panels. | Main power feeds, bus duct terminations, switchgear, PDU input panels, and high-current distribution. |