Choosing the Right DC Cable: Matching Cable Performance to Your Application

1. Define Your Application Requirements

Before you begin comparing cables, define your application’s needs:

- Operating Voltage & Current: How much power must be delivered?

- Load Type: Continuous, intermittent, or variable loads.

- Distance & Layout: Longer runs increase resistance and voltage drop.

- Flexibility Requirements: Stationary vs. frequent movement.

- Compliance Requirements: Industry-specific standards like UL, NEC, or IEC.

2. Key Factors to Evaluate

Once you understand your application requirements, it’s time to evaluate the core factors that will determine which DC cable performs best. These criteria help you narrow down options to ensure safety, compliance, and reliable power delivery.

Need help deciding?

Check our Types of DC Power Cables guide to understand the options, then use this guide to select the right one for your application.

| Factor | What to Consider | Why It Matters |

|---|---|---|

| Conductor Size | Match to required current and acceptable voltage drop. | Undersized conductors overheat and reduce efficiency. |

| Insulation Material | PVC, XLPE, LSZH, etc., depending on temperature and fire safety. | Ensures safety and compliance with building codes. |

| Temperature Rating | Check ambient and operational temperatures. | Prevents premature insulation failure. |

| Shielding/Armoring | Required in high-EMI or mechanically demanding environments. | Reduces noise, enhances durability. |

| Connector Compatibility | Ensure terminals and lugs are rated for the same cable size/type. | Prevents poor connections and energy loss. |

If you’re unsure how these factors apply to your project, our team can help provide expert advice tailored to your application.

3. Plan for Environment and Installation Conditions

Even the best cable can fail early if installed in the wrong environment. Evaluate where and how it will run.

Key Considerations:

- Temperature extremes (ambient and operational)

- Moisture, chemicals, and oil exposure

- UV and sunlight resistance

- Bend radius and flexibility needs

- Conduit, tray, or free-air installation

- Fire safety/smoke requirements (often compliance-driven)

4. Real-World Applications to Narrow Your Choice

Once you’ve defined your specs and environment, look at real-world applications to see how similar environments are wired. This helps you zero in on the most common cable options for your use case.

| Application Scenario | Common Cable Characteristics | Decision Tip |

|---|---|---|

| Data Centers / Telecom | High-flexibility, LSZH insulation, low-voltage drop | Prioritize fire safety and bend radius. |

| Renewable Energy / Solar | UV-stable, high-temperature, corrosion-resistant | Outdoor-rated is critical for lifespan. |

| Temporary Power | Flexible, durable jacket; weather- and abrasion-resistant; suitable for repeated setup and teardown | Select cables rated for temporary use with easy handling and rugged insulation. |

Cablcon can help you translate your application into a cable spec. Whether you need a standard cable or a custom assembly, our team can guide you through the trade-offs. Contact us for an application-specific recommendation.

5. Finalize Your DC Cable Selection

You’ve defined your requirements, evaluated key factors, and considered your environment and application scenarios. The final step isn’t about going it alone, it’s about collaborating with a partner who knows DC power cables inside and out.

How Cablcon Supports You at This Stage:

- Specification Review: Our engineers review your project specs to confirm conductor sizing, insulation type, and environmental suitability.

- Compliance Guidance: We help you verify UL, NEC, and IEC requirements and supply the documentation you’ll need for inspections.

- Custom Assemblies & Cut Lengths: Whether you need standard cables or custom DC power assemblies, we can build to your exact requirements.

- Supply Chain Support: We can confirm lead times, manage inventory, and coordinate delivery schedules to fit your project timelines.

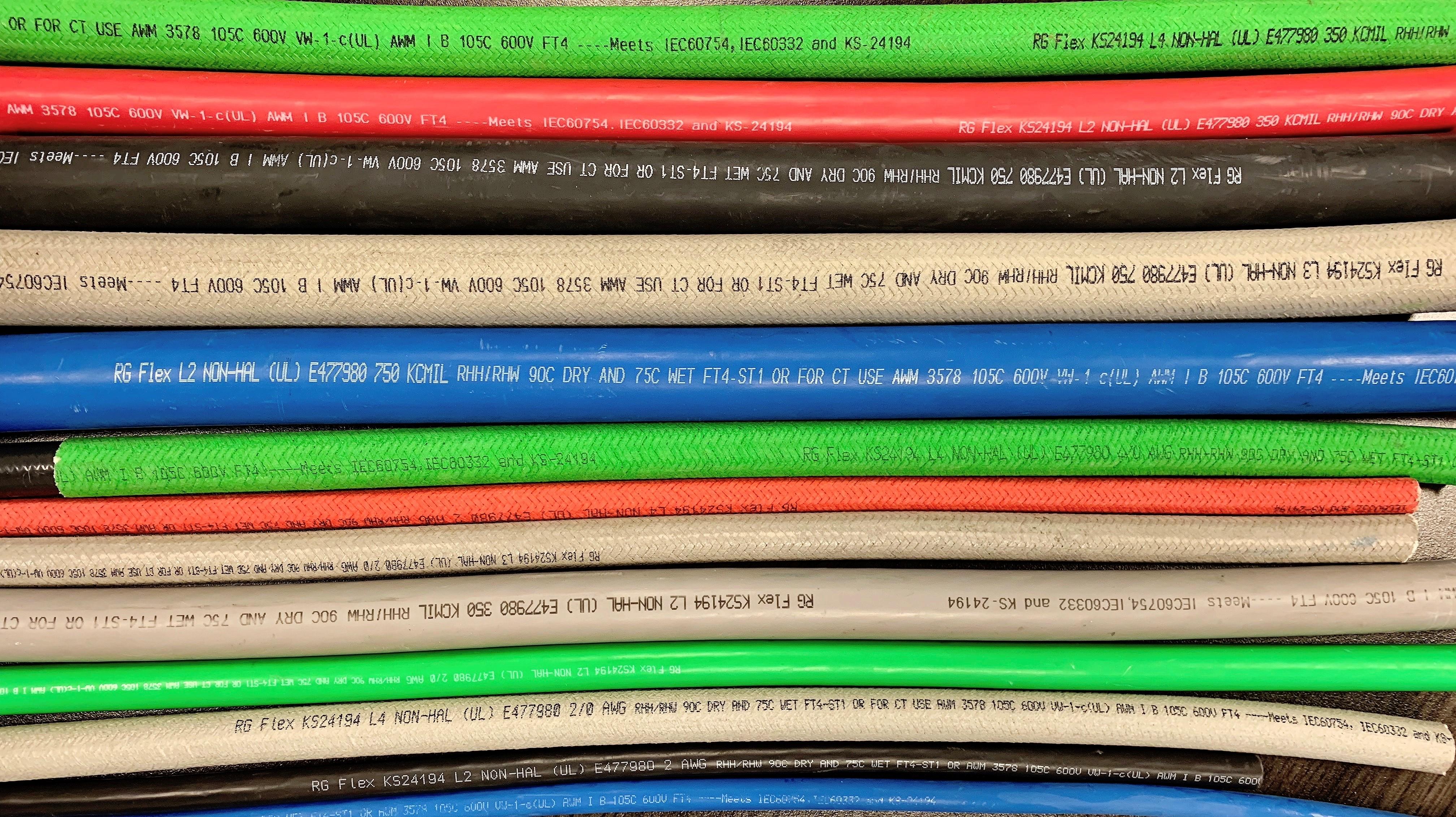

By partnering with Cablcon, you can ensure your final selection is accurate, compliant, and cost-effective. Take the next step by browsing our selection of RG Flex DC power cables to find the right fit for your project.